Thanks to a production area of 8,000 covered sqm consisting of two factories located in Chiuduno (BG), the machining division is able to handle turning, milling and drilling of small and medium-sized mechanical parts (Max weight machined: 20 Ton) as well as third-party assembling of industrial machines for several sectors (Max lifting capacity: 80 Ton).

The company has constantly developed its technological know-how, meeting the needs of its customers, ensuring flexibility and production quality at the highest level, proved by ISO 9001 certificate.

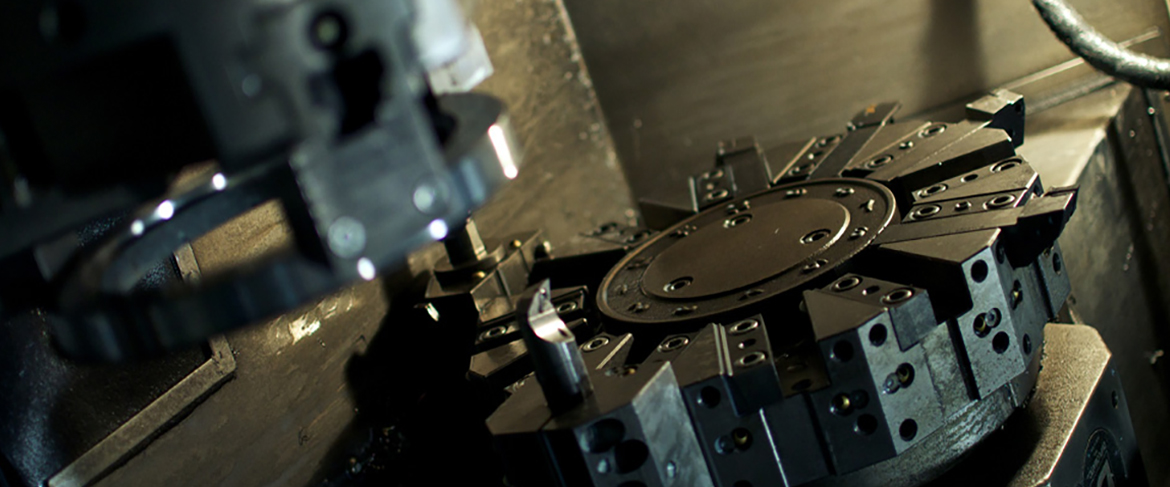

CNC Machine with 'T' Mobile Column

"Pama Speedmat.3/TR20"

Siemens CNC Machine axis strokes: 5000 x 3000 x 2500 mm,

2 turning pallets max weight 20 ton, automatic tools change,

warehouse with 150 positions

90° automatic rotating head

D’andrea head Ø 600 mm

Selca CNC Machine strokes: 3000 x 1400 x 1200 mm

Heidenhain CNC Machine strokes 1100 x 500 x 550 mm

automatic changes tools with 30 positions

Siemens CNC Machine max. diam. 1700 x 1500 mm

automatic changes tool with 60 + 12positions

Max. diam. 850 x 3000 mm

and 1200 x 600 mm

up to 20 Ton capacity

Siemens CNC Machine

axis stroke: 4000 x 2500 x 2000 mm

2 turning pallets max weight 10 ton, automatic tools change

warehouse with 100 positions and

90° automatic rotating head

Selca CNC Machine

Strokes: 1500 x 1000 x 1000 mm

Fanuc CNC Machine

strokes: 3000 x 600 x 600 mm

automatic change tools with 40 positions

Max. diam. 370 x 700 mm

up to a max diam. of 2500 mm

OMAC is equipped with the following traditional machines tools:

N. 5 Parallel lathes tailstock from 150 to 400 mm of diameter

N. 2 Universal Milling machines

N. 3 Radial Drilling machine from 30 to 60 mm of diameter

N. 1 Tangential Grinding machine 1500 mm

N. 1 Round Grinding machine diam. 200 mm x 1500 mm

N. 2 Slotting Machine

N. 1 Vertical broaching machine

N. 1 Saw machine

N. 1 Cutting Machine

N. 3 Press machines from 20 to 150 Ton capacity

Measuring instrument up to a max diam. of 1500 mm

OMAC has at its disposal 4000 sqm of covered area exclusively dedicated to the assembling departments divided between two factories and another 2000 sqm covered warehouse.

Assembly stations are equipped with tools, two painting areas with dry filters, 7 x 5 and 8 x 6 m in size. Assembling departments are equipped with overhead crane having 6, 12, 25 and 60 Ton capacity.

OMAC ITALY s.r.l. | VAT number 04788940163 | Certificati ISO 9001 dal 2003

- Privacy Policy - Cookie Policy - Social Media Policy - Governance